Ungayikhetha Kanjani I-Surface Finish ye-PCB Yakho Design

Ⅲ Isiqondiso sokukhetha kanye namathrendi okuthuthukisa

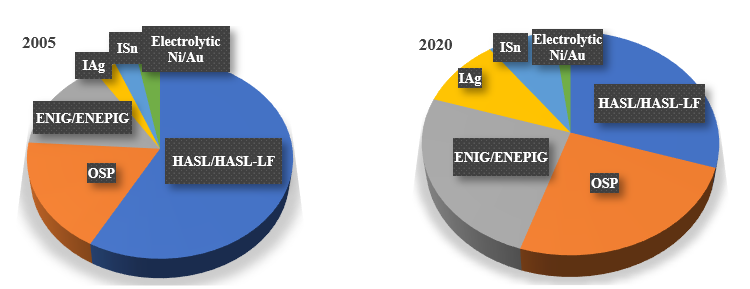

Njengoba ishadi elingenhla libonisa, ukusetshenziswa kwe-PCB surface finishes kuye kwahlukahluka kakhulu eminyakeni engu-20 edlule njengoba ubuchwepheshe buthuthuka kanye nokuba khona kwezikhombisi-ndlela ezivumelana nemvelo.

1) I-HASL Lead Free.Ama-elekthronikhi ehle kakhulu ngesisindo nosayizi ngaphandle kokudela ukusebenza noma ukwethembeka eminyakeni yamuva, lokho kukhawule ukusetshenziswa kwe-HASL ngezinga elikhulu elinendawo engalingani futhi engafanele ukuzwakala kahle, i-BGA, ukubekwa kwezingxenye ezincane futhi kuhlanganiswe emigodini.Ukuqedwa kokulinganisa komoya oshisayo kunokusebenza okuhle kakhulu (ukwethembeka, ukuthengiselana, indawo yokuhlala yomjikelezo oshisayo eminingi kanye nempilo yeshelufu ende) ekuhlanganiseni kwe-PCB enamaphedi amakhulu nesikhala.Ingenye yezinto ezithengekayo nezitholakalayo.Yize ubuchwepheshe be-HASL buye baguqulelwa ekubeni yisizukulwane esisha se-HASL engaholeli emikhawulweni ethobelayo ye-RoHS kanye neziqondiso ze-WEEE, isiphetho sokulinganisa komoya oshisayo sehla safinyelela ku-20-40% embonini yokwenziwa kwe-PCB ekubeni ibuse (3/4) kule ndawo ngeminyaka yawo-1980s.

2) OSP.I-OSP ibidumile ngenxa yezindleko eziphansi kanye nenqubo elula nokuba namaphedi e-co-planar.Kusamukelwe ngenxa yalokhu.Inqubo ye-organic coating ingasetshenziswa kabanzi kuma-PCB ajwayelekile noma ama-PCB athuthukile njengephimbo elihle, i-SMT, amabhodi wokuphakela.Ukuthuthukiswa kwakamuva kwe-plate multilayer ye-organic coating kuqinisekisa ukuthi i-OSP ime imijikelezo eminingi yokunamathisela.Uma i-PCB ingenazo izimfuneko zokusebenza koxhumano olungaphezulu noma imikhawulo yempilo yeshalofu, i-OSP izoba inqubo efanelekile yokuqeda indawo.Kodwa-ke amaphutha ayo, ukuzwela ekuphatheni umonakalo, impilo yeshalofu emfushane, ukungaziphathi kahle kanye nobunzima ukukuhlola kwehlisa ijubane layo ukuze iqine kakhulu.Kulinganiselwa ukuthi cishe ama-25% -30% ama-PCB okwamanje asebenzisa inqubo yokuhlanganisa izinto eziphilayo.

3) ENIG.I-ENIG isiphetho esidume kakhulu phakathi kwama-PCB athuthukile nama-PCB asetshenziswa endaweni enokhahlo, ngokusebenza kwayo okuhle endaweni ehleliwe, ukuqina nokuqina, ukumelana nokubola.Iningi labakhiqizi be-PCB bane-electroless nickel / imigqa yegolide yokucwiliswa ezimbonini zabo zamabhodi wesifunda noma ama-workshops.Ngaphandle kokucabangela izindleko nokulawulwa kwenqubo, i-ENIG izoba ezinye izindlela ezikahle ze-HASL futhi ikwazi ukusetshenziswa kabanzi.I-electroless nickel/igolide lokucwiliswa lalikhula ngokushesha ngeminyaka yawo-1990s ngenxa yokuxazulula inkinga yokucaba yokulinganisa komoya oshisayo kanye nokususwa kokuguquguquka okuhlanganiswe ngemvelo.I-ENEPIG njengenguqulo ebuyekeziwe ye-ENIG, ixazulule inkinga yephedi emnyama ye-electroless nickel/ igolide lokucwiliswa kodwa isabiza.Ukusetshenziswa kwe-ENIG kunokuncipha kancane kusukela ekukhuphukeni kwezindleko eziphansi zokumiselela njenge-Immersion Ag, Immersion Tin ne-OSP.Kulinganiselwa ukuthi i-15-25% yama-PCB okwamanje amukela lokhu kuqedwa.Uma kungekho ukuboshelwa kwesabelomali, i-ENIG noma i-ENEPIG iyindlela ekahle ezimweni eziningi ikakhulukazi kuma-PCB anezidingo ezidinga kakhulu zomshwalense wekhwalithi ephezulu, ubuchwepheshe bephakheji eliyinkimbinkimbi, izinhlobo eziningi zokunamathisela, izimbobo, i-wire bonding, kanye nobuchwepheshe be-press fit fit, njll..

4) Ukucwiliswa kwesiliva.Njengokushintshwa okushibhile kwe-ENIG, isiliva lokucwiliswa elinezakhiwo zokuba nendawo eyisicaba kakhulu, ukuqhuba kahle okuhle, impilo yeshalofu emaphakathi.Uma i-PCB yakho idinga ukuphakama okuhle / i-BGA SMT, ukubekwa kwezingxenye ezincane, futhi idinga ukugcina ukusebenza kokuxhumeka kahle kuyilapho unesabelomali esiphansi, isiliva lokucwiliswa liyinketho oyikhethayo.I-IAg isetshenziswa kakhulu emikhiqizweni yezokuxhumana, ezimotweni, nasezindaweni ezizungezile zekhompiyutha, njll. Ngenxa yokusebenza kukagesi okungenakuqhathaniswa, yamukelwa ngemiklamo yefrikhwensi ephezulu.Ukukhula kwesiliva lokucwiliswa kuhamba kancane (kodwa lisakhuphuka) ngenxa yokwehla okunengqondo ukonakala nokuba nama-solder joint voids.Kukhona cishe u-10% -15% wama-PCB asebenzisa lesi siphetho okwamanje.

5) Ithini lokucwiliswa.I-Immersion Tin yethulwe ohlelweni lokuqeda ngaphezulu iminyaka engaphezu kwengama-20.I-automation yokukhiqiza ingumshayeli omkhulu we-ISn surface finish.Kungenye inketho engabizi kakhulu yezidingo zendawo eyisicaba, ukubekwa kwezingxenye zephimbo elihle kanye nokulingana kokucindezela.I-ISn ifaneleka ngokukhethekile izindiza ezingemuva zokuxhumana ngaphandle kwanoma yiziphi izici ezintsha ezengezwe phakathi nenqubo.I-Tin Whisker kanye newindi elifushane lokusebenza kuwumkhawulo omkhulu wokusetshenziswa kwayo.Izinhlobo eziningi zokuhlanganisa azinconywa uma kunikezwe ukwanda kongqimba lwe-intermetallic ngesikhathi sokufakwa kwe-soldering.Ngaphezu kwalokho, ukusetshenziswa kwenqubo yokucwiliswa kwe-tin kukhawulelwe ngenxa yokuba khona kwama-carcinogens.Kulinganiselwa ukuthi cishe u-5% -10% wama-PCB okwamanje asebenzisa inqubo yokucwiliswa kwethini.

6) Electrolytic Ni/Au.I-Electrolytic Ni/Au ingumsunguli we-PCB surface treatment technology.Ivele ngesimo esiphuthumayo samabhodi esekethe Aphrintiwe.Kodwa-ke, izindleko eziphakeme kakhulu zikhawulela ngokumangalisayo ukusetshenziswa kwayo.Namuhla, igolide Elithambile lisetshenziselwa ikakhulukazi izintambo zegolide ekufakweni kwe-chip;Igolide eliqinile lisetshenziswa kakhulu ekuxhumekeni kukagesi ezindaweni ezingadayisi njengeminwe yegolide nabathwali be-IC.Ingxenye ye-Electroplating Nickel-gold icishe ibe ngu-2-5%.

Emuvakuma-Blogs

Isikhathi sokuthumela: Nov-15-2022