Kuthunyelwe: Feb 15, 2022

Izigaba:Amabhulogi

Omaka:pcb, pcbs, pcba, pcb inhlangano, smt, i-stencil

Iyini i-PCB Stencil?

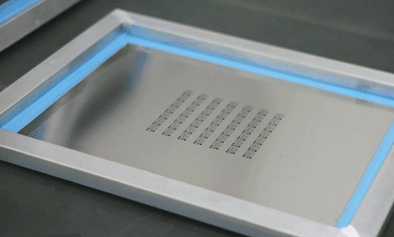

I-PCB Stencil, eyaziwa nangokuthi i-Steel mesh, iyishidi le-stai

insimbi engenasici enezimbobo zokusika ze-laser ezisetshenziselwa ukudlulisa inani elinembile lokunamathisela kwe-solder endaweni eqondile eqokiwe ku-PCB engenalutho yokubekwa kwezingxenye zokukhweza.I-stencil yakhiwe ngohlaka lwe-stencil, i-wire mesh neshidi lensimbi.Kunezimbobo eziningi ku-stencil, futhi izikhundla zalezi zimbobo zihambisana nezikhundla ezidinga ukuphrinta ku-PCB.Umsebenzi oyinhloko we-stencil ukufaka ngokunembile inani elifanele lokunamathisela i-solder kuma-pads ukuze i-solder joint phakathi kwe-pad nengxenye iphelele ngokuxhuma kukagesi namandla omshini.

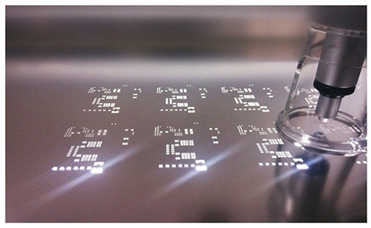

Uma isetshenziswa, beka i-PCB ngaphansi kwe-stencil, Kanye

i-stencil iqondaniswe kahle phezulu kwebhodi, i-solder paste isetshenziswa phezu kokuvuleka.

Khona-ke inhlama ye-solder ivuza endaweni ye-PCB ngezimbobo ezincane endaweni engaguquki ku-stencil.Lapho i-foil yensimbi ihlukaniswa nebhodi, i-solder paste izohlala phezu kwebhodi lesifunda, ilungele ukubekwa kwamadivayisi okufakwa phezulu (ama-SMD).Ukunamathisela okuncane kwe-solder kuvinjiwe ku-stencil, kulapho kufakwa khona ku-PCB.Le nqubo ingaphindaphindwa ngokunembile, ngakho yenza inqubo ye-SMT isheshe futhi ingaguquguquki futhi iqinisekise ukonga kwezindleko ze-PCB Assembly.

Yenziwe ngani i-PCB Stencil?

I-SMT stencil yenziwe ngokuyinhloko ngohlaka lwe-stencil, i-mesh kanye

ishidi lensimbi engagqwali, kanye neglu.Uhlaka lwe-stencil olusetshenziswa ngokuvamile luwuhlaka olunamathiselwe ku-wire mesh eneglue, okulula ukuthola ukushuba kweshidi lensimbi, okuvamise ukuba ngu-35 ~ 48N / cm2.I-Mesh ingeyokulungisa ishidi lensimbi nohlaka.Kunezinhlobo ezimbili zamameshi, insimbi engagqwali yocingo enezikhala kanye ne-polymer polyester mesh.Owokuqala unganikeza ukushuba okuzinzile nokwanele kodwa kulula ukuwohloka nokuguga.Okwakamuva kodwa kungahlala isikhathi eside uma kuqhathaniswa nensimbi engenasici.Ishidi le-stencil elamukelwa ngokuvamile liyishidi lensimbi engu-301 noma engu-304 elithuthukisa ngokusobala ukusebenza kwe-stencil ngokusebenzisa izici zayo ezinhle zokukhanda.

Indlela Yokukhiqiza Ye-stencil

Kunezinhlobo eziyisikhombisa zama-stencil nezindlela ezintathu zokwenza ama-stencil: i-chemical etching, i-laser cutting kanye ne-electroforming.Ngokuvamile kusetshenziswa i-laser steel stencil.Las

I-er stencil isetshenziswa kakhulu embonini ye-SMT, ebonakala ngokuthi:

Ifayela ledatha lisetshenziswa ngokuqondile ukunciphisa iphutha lokukhiqiza;

Ukunemba kwesikhundla sokuvula kwe-SMT stencil kuphezulu kakhulu: lonke iphutha lenqubo ngu-≤± 4 μ m;

Ukuvulwa kwe-SMT stencil kune-geometry, okuyi-conduci

Vele ukuphrinta nokubunjwa kwe-solder paste.

Ukugeleza kwenqubo yokusika i-laser: ukwenza ifilimu i-PCB, ukuthatha izixhumanisi, ifayela ledatha, ukucubungula idatha, ukusika i-laser, ukugaya.Inqubo inokunemba okuphezulu kokukhiqizwa kwedatha kanye nomthelela omncane wezinto ezihlosiwe;Ukuvulwa kwe-trapezoidal kulungele ukudilizwa, kungasetshenziselwa ukusika ngokunemba, ukushibhile kwentengo.

Izidingo ezijwayelekile kanye nezimiso ze-PCB Stencil

1. Ukuze uthole ukuphrinta okuphelele kokunamathisela kwe-solder kuma-PCB pads, isikhundla esithile kanye nokucaciswa kuzoqinisekisa ukunemba okuphezulu kokuvula, futhi ukuvulwa kufanele kuhambisane ngokuqinile nendlela eshiwo yokuvula okubhekiselwe kumamaki we-fiducial.

2. Ukuze ugweme ukukhubazeka kwe-solder njengokuhlanganisa ibhuloho nobuhlalu be-solder, ukuvulwa okuzimele kuzoklama okuncanyana kunosayizi wephedi ye-PCB.ububanzi obuphelele akumele budlule ku-2mm.Indawo yephedi ye-PCB kufanele njalo ibe nkulu kunezingxenye ezimbili kwezintathu zendawo yangaphakathi yodonga lokuvula lwe-stencil.

3. Lapho welula anezikhala, ngokuqinile yilawule, futhi pa

y Ukunaka okukhethekile ebangeni lokuvula, okumele libe livundlile futhi ligxile.

4. Ngendawo yokuphrinta njengenhla, ukuvuleka okuphansi kwe-mesh kuzoba ngu-0.01mm noma u-0.02mm ububanzi kunokuvulwa okungaphezulu, okungukuthi, ukuvuleka kuzoguqulwa kube yi-conical ukuze kube lula ukukhululwa okusebenzayo kwe-solder paste futhi kunciphise ukuhlanza. izikhathi ze-stencil.

5. Udonga lwemeshi kufanele lube bushelelezi.Ikakhulukazi ku-QFP ne-CSP enezikhala ezingaphansi kuka-0.5mm, umphakeli kudingeka aqhube ukupholisa ngogesi phakathi nenqubo yokukhiqiza.

6. Ngokuvamile, ukucaciswa kokuvula i-stencil kanye nokuma kwezingxenye ze-SMT kuhambisana nephedi, futhi isilinganiso sokuvula singu-1:1.

7. Ukuqina okunembile kweshidi le-stencil kuqinisekisa ukukhululwa

yenani elifiswayo lokunamathisela i-solder ngokuvula.Ukufakwa kwe-solder eyengeziwe kungabangela ukuhlanganisa i-solder ngenkathi ukufakwa kwe-solder encane kuzodala amalunga abuthakathaka e-solder.

Indlela yokuklama i-PCB Stencil?

1. Iphakethe le-0805 linconywa ukusika amaphedi amabili wokuvula ngo-1.0mm, bese wenza umbuthano we-concave B = 2 / 5Y;A = 0.25mm noma a = 2 / 5 * l ubuhlalu be-anti tin.

2. I-Chip 1206 nangaphezulu: ngemva kokuba amaphedi amabili ehanjiswe ngaphandle ngo-0.1mm ngokulandelana, yenza indilinga yangaphakathi ye-concave B = 2 / 5Y;A = 2 / 5 * l ukwelashwa kwe-anti tin bead.

3. Ku-PCB ene-BGA, isilinganiso sokuvula se-stencil esinezikhala sebhola esingaphezu kuka-1.0mm singu-1:1, kanti isilinganiso sokuvula se-stencil esinesikhala sebhola esingaphansi kuka-0.5mm singu-1:0.95.

4. Kuyo yonke i-QFP ne-SOP enokuphakama okungu-0.5mm, isilinganiso sokuvula

o kububanzi obuphelele bokuqondisa ngu-1:0.8.

5. Isilinganiso sokuvula esiqondisweni sobude singu-1:1.1, ne-0.4mm pitch QFP, ukuvuleka kobubanzi obuphelele bungu-1:0.8, ukuvulwa kobude ngu-1:1.1, nonyawo olujikelezayo lwangaphandle.I-Chamfer radius r = 0.12mm.Ububanzi obuphelele bokuvula bento ye-SOP enokuphakama okungu-0.65mm buncishiswe ngo-10%.

6. Uma i-PLCC32 ne-PLCC44 yemikhiqizo evamile inembobo, ububanzi bendawo bungu-1:1 futhi ubude bungu-1:1.1.

7. Kumadivayisi ahlanganisiwe we-SOT, isilinganiso sokuvula

yokuphela kwephedi elikhulu ngu-1:1.1, ububanzi bengqikithi yesiphetho sephedi encane ngu-1:1, kanti ubude bendawo bungu-1:1.

KanjaniUkusebenzisa i-PCB Stencil?

1. Phatha ngokucophelela.

2. I-stencil izohlanzwa ngaphambi kokusetshenziswa.

3. I-solder paste noma i-glue ebomvu izosetshenziswa ngokulinganayo.

4. Lungisa ingcindezi yokuphrinta ibe ngcono kakhulu.

5. Ukusebenzisa ukuphrinta kwebhodi lokunamathisela.

6. Ngemuva kokushaywa kwe-scraper, kungcono ukuma imizuzwana engu-2 ~ 3 ngaphambi kokudiliza, futhi usethe isivinini sokudiliza singasheshi kakhulu.

7. I-stencil izohlanzwa ngesikhathi, igcinwe kahle ngemva kokusetshenziswa.

Isevisi Yokukhiqiza I-Stencil ye-PCB ShinTech

I-PCB ShinTech inikezela ngezinsizakalo zokukhiqiza ama-laser ensimbi engagqwali.Senza ama-stencil anobukhulu obuyi-100 μm, 120 μm, 130µm, 150 μm, 180 μm, 200 μm, 250 μm no-300 μm.Ifayela ledatha elidingekayo ukwenza i-laser stencil kufanele libe nesendlalelo sokunamathisela solder se-SMT, idatha ye-fiducial mark, isendlalelo sohlaka lwe-PCB nongqimba lwezinhlamvu, ukuze sikwazi ukuhlola izinhlangothi zangaphambili nangemuva zedatha, isigaba sengxenye, njll.

Uma udinga ikhotheshini sicela uthumele amafayela akho kanye nombuzo kusales@pcbshintech.com.

Isikhathi sokuthumela: Jun-10-2022