Ifakwe Ngezimbobo Izinqubo ze-PTH efektri ye-PCB---Electroless Chemical Copper Plating

Cishe bonkePCBs anezendlalelo ezikabili noma izendlalelo eziningi zisebenzisa izimbobo (PTH) ukuxhuma amakhondakta phakathi kwezingqimba zangaphakathi noma ezingaphandle, noma ukubamba izingxenye zezintambo zokuhola.Ukuze kuzuzwe lokho, izindlela ezinhle ezixhumene ziyadingeka ukuze umsinga ugeleze emigodini.Nokho, ngaphambi plating inqubo, ngokusebenzisa izimbobo non-conductive ngenxa ephrintiwe amabhodi wesifunda akhiwa non-conductive composite substrate impahla (epoxy-glass, phenolic-paper, polyester-glass, njll).Ukuze kukhiqizwe ukusebenziseka kwezinye izindlela zembobo, cishe ama-microns angu-25 (1 mil noma 0.001 in.) ekhopha noma ngaphezulu ashiwo umklami webhodi lesifunda kudingeka afakwe ngogesi ezindongeni zezimbobo ukuze kwakhiwe uxhumano olwanele.

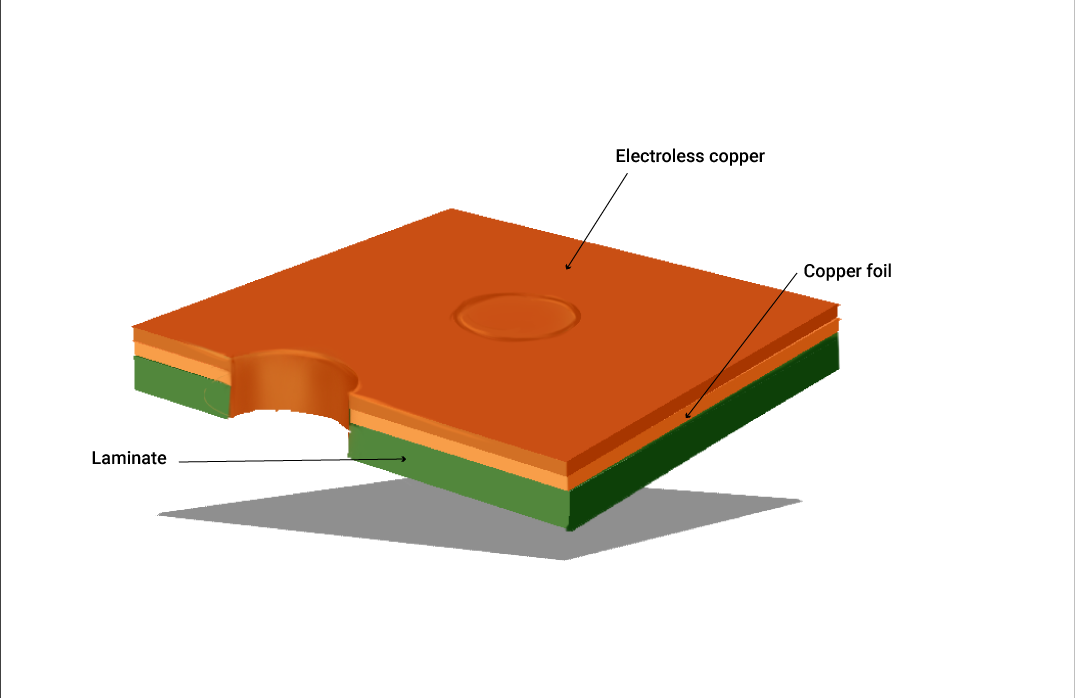

Ngaphambi kwe-electrolytical copper plating, isinyathelo sokuqala i-chemical copper plating, ebizwa nangokuthi i-electroless copper deposition, ukuze kutholwe ungqimba lokuqala lwe-conductive odongeni lwezimbobo zamabhodi ezintambo aphrintiwe.Ukusabela kwe-autocatalytic oxidation-reduction kwenzeka phezu kwe-substrate engaphenduki edlula izimbobo.Phezu kodonga ijazi lethusi elincanyana kakhulu elingama-micrometer angu-1-3 lifakwe ngamakhemikhali.Inhloso yawo ukwenza imbobo ihambe ngokwanele ukuze ivumele ukwakheka okwengeziwe ngethusi elifakwe ngogesi kugqinsi olushiwo umklami webhodi lezintambo.Ngaphandle kwethusi, singasebenzisa i-palladium, i-graphite, i-polymer, njll.Kodwa ithusi iyindlela engcono kakhulu yonjiniyela we-elekthronikhi ngezikhathi ezivamile.

Njengoba ithebula le-IPC-2221A 4.2 lithi ubuncane bokujiya bethusi obusetshenziswa indlela yokucwenga yethusi engenawo ugesi ezindongeni ze-PTH ngokufakwa kwethusi okumaphakathi ngu-0.79 mil wekilasi Ⅰ kanye neClass Ⅱ kanye no-0.98 milikilasiⅢ.

Ulayini wekhemikhali we-copper deposition ulawulwa ngokugcwele ngekhompuyutha futhi amaphaneli athwalwa ngochungechunge lwamakhemikhali namanzi okugeza okugeza nge-crane engaphezulu.Ekuqaleni, amaphaneli e-pcb aphathwa ngaphambilini, asuse yonke insalela ekubholeni futhi anikeze ukuhwalala okuhle kakhulu kanye nokuqina kwe-electro ukuze kufakwe amakhemikhali ethusi.Isinyathelo esibalulekile yinqubo ye-permanganate desmear yezimbobo.Phakathi nenqubo yokwelashwa, ungqimba oluncane lwe-epoxy resin luqoshwa kude nomkhawulo wengqimba yangaphakathi kanye nezindonga zemigodi, ukuqinisekisa ukunamathela.Khona-ke zonke izindonga zembobo zicwiliswa emanzini asebenzayo ukuze zithole imbewu ngezinhlayiya ezincane ze-palladium emabhathini asebenzayo.Ukugeza kugcinwa ngaphansi kokunyakaza komoya okuvamile futhi amaphaneli ahlala ehamba ebhavini ukuze asuse amabhamuza omoya okungenzeka akheke ngaphakathi kwezimbobo.Ungqimba oluncane lwethusi olufakwe phezu kwayo yonke indawo yephaneli kanye nezimbobo ezibhoboziwe ngemva kokugeza kwe-palladium.Ukufakwa kwe-electroless kusetshenziswa i-palladium kunikeza ukunamathela okuqine kakhulu kokunamathela kwethusi ku-fiberglass.Ekugcineni kuhlolwa ukuhlolwa ukuze kuhlolwe i-porosity kanye nobukhulu bejazi lethusi.

Isinyathelo ngasinye sibalulekile kunqubo yonke.Noma yikuphi ukuphathwa kabi enqubweni kungabangela lonke iqoqo lamabhodi e-PCB ukuthi limosheke.Futhi ikhwalithi yokugcina ye-pcb ilele kakhulu kulezo zinyathelo ezishiwo lapha.

Manje, ngezimbobo zokuqhuba, ukuxhumana kukagesi phakathi kwezingqimba zangaphakathi nezingaphandle ezisungulwe kumabhodi wesekethe.Isinyathelo esilandelayo ukukhulisa ithusi kulezo zimbobo kanye nezendlalelo ezingaphezulu neziphansi zamabhodi okufaka izintambo zibe ukujiya okuthile - i-copper electroplating.

Imigqa yokucwenga ye-electroless yethusi yamakhemikhali ezenzakalelayo egcwele ku-PCB ShinTech ene-Cutting edge PTH Technology.

Isikhathi sokuthumela: Jul-18-2022