I-HDI PCB yenza embonini ye-PCB ezenzakalelayo --- OSP surface finish

Kuthunyelwe:Feb 03, 2023

Izigaba: Amabhulogi

Omaka: pcb,pcba,umhlangano we-pcb,ukukhiqiza i-pcb, pcb surface finish,HDI

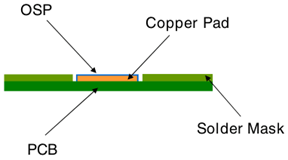

I-OSP imele i-Organic Solderability Preservative, ebuye ibizwe ngokuthi i-circuit board organic coating eyenziwe ngabakhiqizi be-PCB, idume ngokuqedwa kwendawo Yebhodi Yesifunda Ephrintiwe ngenxa yezindleko eziphansi nokusebenziseka kalula ekwenzeni i-PCB.

I-OSP isebenzisa ngokwekhemikhali inhlanganisela yezinto eziphilayo ungqimba lwethusi oluveziwe lwakha amabhondi ethusi ngokukhetha ngaphambi kokusoda, yakha ungqimba lwe-organic metallic ukuvikela ithusi eliveziwe ekugqwaleni.Ubukhulu be-OSP, buncane, buphakathi kuka-46µin (1.15µm)-52µin(1.3µm), kukalwa ngo-A° (angstrom).

I-Organic Surface Protectant isobala, akulula ukuthi ihlolwe ngokubonakalayo.Ku-soldering elandelayo, izosuswa ngokushesha.Inqubo yokucwiliswa kwamakhemikhali ingasetshenziswa kuphela ngemva kokuba zonke ezinye izinqubo sezenziwe, okuhlanganisa Ukuhlolwa kukagesi kanye Nokuhlola.Ukusebenzisa i-OSP surface finish ku-PCB ngokuvamile kuhilela indlela yamakhemikhali ehanjiswayo noma ithangi lokucwilisa eliqondile.

Inqubo ngokuvamile ibukeka kanjena, ngamarinse phakathi kwesinyathelo ngasinye:

1) Ukuhlanza.

2) Ukuthuthukiswa kwe-Topography: Indawo yethusi eveziwe i-micro-etching ukuze kwandiswe isibopho phakathi kwebhodi ne-OSP.

3) I-Acid hashaza ngesisombululo se-sulfuric acid.

4) Isicelo se-OSP: Kuleli qophelo lenqubo, isisombululo se-OSP sisetshenziswa ku-PCB.

I-5) Hlanza i-Deionization: Isixazululo se-OSP sifakwe ama-ion ukuvumela ukuqedwa kalula ngesikhathi sokudayiswa.

6) Yomisa: Ngemva kokusetshenziswa kwe-OSP, i-PCB kufanele yomiswe.

I-OSP surface finish ingenye yeziqephu ezidume kakhulu.Kuyindlela yokonga kakhulu, evumelana nemvelo yokukhiqiza amabhodi esekethe aphrintiwe.Inganikeza indawo yamaphedi e-co-planar ukuze uthole amaphuzu amahle/i-BGA/ukubekwa kwezingxenye ezincane.Indawo ye-OSP ilungiseka kakhulu, futhi ayidingi ukunakekelwa okuphezulu kwemishini.

Kodwa-ke, i-OSP ayiqinile njengoba bekulindelekile.Inobubi bayo.I-OSP iyazwela ekuphatheni futhi idinga ukuphathwa ngokuqinile ukuze igweme ukuklwebheka.Imvamisa, ukusoda okuningi akuphakanyiswa ngoba ukusoda okuningi kungalimaza ifilimu.Impilo yeshelufu layo imfishane phakathi kwazo zonke iziqephu ezingaphezulu.Amabhodi kufanele ahlanganiswe ngokushesha ngemva kokufaka i-coating.Eqinisweni, abahlinzeki be-PCB banganweba impilo yayo yeshalofu ngokuphinda kwenziwe kabusha isiphetho.I-OSP inzima kakhulu ukuyihlola noma ukuyihlola ngenxa yemvelo yayo esobala.

Okuhle:

1) I-lead-free

2) Indawo eyisicaba, ilungele amaphedi e-fine-pitch (BGA, QFP...)

3) Ukugqoka okuncane kakhulu

4) Ingasetshenziswa kanye nezinye iziqephu (isb. OSP+ENIG)

5) Izindleko eziphansi

6) Ukusebenza kabusha

7) Inqubo elula

Ububi:

1) Ayilungele i-PTH

2) Ukuphatha Okuzwelayo

3) Impilo yeshelufu emfushane (<6 izinyanga)

I-4) Ayifanele ubuchwepheshe be-crimping

5) Ayilungele ukugeleza kabusha okuningi

6) I-Copper izodalulwa emhlanganweni, idinga ukugeleza okunamandla

7) Kunzima ukuhlola, kungase kubangele izinkinga ekuhlolweni kwe-ICT

Ukusetshenziswa okujwayelekile:

I-1) Amadivayisi okuphakama okuhle: Lokhu kuqedwa kungcono kakhulu ukukusebenzisa kumadivayisi okuphakama amahle ngenxa yokuntuleka kwamaphedi ahlangene noma izindawo ezingalingani.

2) Amabhodi eziphakeli: Ukusetshenziswa kwe-OSP kuyahlukahluka kusuka kuzinhlelo zokusebenza ezisezingeni eliphansi kuye kumabhodi eseva enziwe imvamisa ephezulu.Lokhu kuhlukahluka okubanzi kokusebenziseka kuyenza ilungele izinhlelo zokusebenza eziningi.Ibuye isetshenziselwe ukuqedela okukhethiwe.

3) Ubuchwepheshe be-Surface Mount (SMT): I-OSP isebenza kahle ekuhlanganiseni kwe-SMT, uma udinga ukunamathisela ingxenye ngokuqondile endaweni ye-PCB.

Emuvakuma-Blogs

Isikhathi sokuthumela: Feb-02-2023