PCB Fabrication & PCB Assembly Amakhono

Amakhono Okukhiqiza we-PCB

| Izinto | I-PCB ejwayelekile | I-PCB ethuthukisiwe |

| Amandla Okukhiqiza | 40,000 m2ngenyanga | 40,000 m2ngenyanga |

| Isendlalelo | 1, 2, 4, kuze kufike kweziyi-10 | 1, 2, 4, kufika ku-50 izendlalelo |

| Okubalulekile | FR-4, CEM-1, Aluminium, njll. | I-FR-4 (Ejwayelekile kuya kwephezulu Tg), High CTI FR-4, CEM-1, CEM-3, Polymide (PI), Rogers, Glass Epoxy, Aluminium Base, Rohs Compliant, RF, njll. |

| Uhlobo lwe-PCB | Iqinile | Iqinile, Iyavumelana nezimo, Iqinile-Eguquguqukayo |

| Okuncane.Ukushuba Okubalulekile | 4mil/0.1mm(2-12 layer), 2mil/0.05mm (≥13layer) | 4mil/0.1mm(2-12 layer), 2mil/0.06mm (≥13layer) |

| Prepreg Type | 1080, 2116, 765-8, 106, 3313, 2165, 1500 | 1080, 2116, 765-8, 106, 3313, 2165, 1500 |

| Usayizi Webhodi Eliphezulu | 26''*20.8 '' /650mm*520mm | Yenza ngokwezifiso |

| Ukuqina Kwebhodi | 0.4mm/16mil-2.4mm/96mil | 0.2mm/8mil-10.0mm/400mil |

| Ukujiya Ukubekezelelana | ±0.1mm (Ukuqina Kwebhodi<1.0mm);±10% (Ukuqina Kwebhodi≥1.0mm) | ±0.1mm (Ukuqina Kwebhodi<1.0mm);±4% (Ukuqina Kwebhodi≥1.0mm) |

| Ukuchezuka kwe-Dimensional | ±0.13mm/5.2mil | ±0.10mm/4 mil |

| I-Warping angle | 0.75% | 0.75% |

| Ukuqina Kwethusi | 0.5-10 oz | 0.5-18 oz |

| Ukubekezelela Ukuqina Kwethusi | ±0.25 oz | ±0.25 oz |

| Okuncane.Ububanzi Bomugqa/Isikhala | 4mil/0.1mm | 2mil/0.05mm |

| Okuncane.I-Drill Hole Diameter | 8mil/0.2mm (umakhenikha) | 4mil/0.1mm (i-laser), 6mil/0.15mm (umshini) |

| Ukuqina Kwezindonga ze-PTH | ≥18μm | ≥20μm |

| I-PTH Hole Tolerance | ±3mil/0.076mm | ±2mil/0.05mm |

| I-NPTH Hole Tolerance | ±2mil/0.05mm | ±1.5mil/0.04mm |

| Ubukhulu.I-Aspect ratio | 12:1 | 15:1 |

| Okuncane.Izimpumputhe/Wangcwatshwa Nge | 4mil/0.1mm | 4mil/0.1mm |

| I-Surface Qeda | I-HASL, i-OSP, i-Immersion Gold | I-HASL, i-OSP, i-Nickle, i-Immersion Gold, i-Imm Tin, i-Imm Silver, njll. |

| I-Solder Mask | Okuluhlaza, Okubomvu, Okumhlophe, Okuphuzi, Okuluhlaza okwesibhakabhaka, Okumnyama | Okuhlaza, Okubomvu, Okumhlophe, Okuphuzi, Okuluhlaza okwesibhakabhaka, Okumnyama, Okuwolintshi, Okunsomi, njll. Okwenziwa ngendlela oyifisayo |

| I-Solder Mask offset | ±3mil/0.076mm | ±2mil/0.05mm |

| Umbala Wesikrini Silk | Okuluhlaza, Okubomvu, Okumhlophe, Okuphuzi, Okuluhlaza okwesibhakabhaka, Okumnyama | Okuhlaza, Okuluhlaza okwesibhakabhaka, Okumnyama, Okumhlophe, Okubomvu, Okunsomi, Okungafihli, Okumpunga, Okuphuzi, Okuwolintshi, njll. Okungenziwa ngendlela oyifisayo |

| I-Silkscreen Min.Ububanzi Bomugqa | 0.006'' noma 0.15mm | 0.006'' noma 0.15mm |

| I-Impedans Control | ±10% | ±5% |

| Ukubekezelela Indawo Yezimbobo | ±0.05mm, ±0.13mm (2ndumgodi wabhoboza ku-1stindawo yomgodi) | ±0.05mm, ±0.13mm (2ndumgodi wabhoboza ku-1stindawo yomgodi) |

| PCB Cutting | I-Shear, i-V-Score, i-Tab-routed | I-Shear, i-V-Score, i-Tab-routed |

| Ukuhlolwa nokuhlolwa | I-AOI, Ukuhlolwa Kwe-Fly Probe, Ukuhlolwa kwe-ET, Ukuhlola I-Microsection, Ukuhlolwa Kokuqina, Ukuhlolwa Kwe-Impedance, njll. | I-AOI, Ukuhlolwa Kwe-Fly Probe, Ukuhlolwa kwe-ET, Ukuhlola I-Microsection, Ukuhlolwa Kokuqina, Ukuhlolwa Kwe-Impedance, njll. |

| Izinga Lekhwalithi | IPC Ikilasi II | IPC Class II, IPC Class III |

| Isitifiketi | UL, ISO9001:2015, ISO14001:2015, TS16949:2009, RoHS njll. | UL, ISO9001:2008, ISO14001:2008, TS16949:2009, AS9100, RoHS, njll. |

Amakhono Omhlangano we-PCB

| Amasevisi | I-Turnkey-kusuka ekukhiqizeni amabhodi angenalutho, Ukuthola izingxenye, ukuhlanganisa, iphakheji, ukulethwa;Izinqubo zekhithidi/ingxenye ye-turkey-ingxenye yohlu olungenhla ngokwezidingo zekhasimende. |

| Izinsiza | Imigqa ye-SMT yangaphakathi engu-15, imigqa emi-3 yendlu ephuma emgodini, imigqa emi-3 yokugcina yasendlini |

| Izinhlobo | I-SMT, Thru-hole, Mixed (SMT/Thru-hole), Ukubekwa okukodwa noma okukabili |

| Isikhathi esiholayo | I-Quickturn, i-Prototype noma inani elincane: izinsuku ezingu-3-7 zokusebenza (zonke izingxenye sezilungile).I-Misa Order: izinsuku zokusebenza ezingu-7-28 (zonke izingxenye sezilungile);Ukulethwa okuhleliwe kuyatholakala |

| Ukuhlola Imikhiqizo | Ukuhlolwa kwe-X-ray, i-ICT (In-Circuit Testing), 100% BGA X-Ray Inspection, Ukuhlolwa kwe-AOI (Ukuhlola Okuzenzakalelayo Kokuhlola), Ukuhlola I-Jig/Isikhunta, Ukuhlola Okusebenzayo, Ukuhlola Ingxenye Yomgunyathi (kohlobo lomhlangano wekhithi), njll. |

| Imininingwane ye-PCB | I-Rigid, i-Metal Core, i-Flexible, i-Flex-Rigid |

| Ubuningi | I-MOQ: 1 pc.I-prototype, ukuhleleka okuncane, ukukhiqizwa ngobuningi |

| Ukuthengwa kwezingxenye | I-Turnkey, Ikhithikhithi/Ikhithi Eyingxenye |

| Izinsimbi | Laser ukusika insimbi engagqwali |

| I-Nano-coating iyatholakala | |

| Izinhlobo ze-soldering | I-Lead, engenawo umthofu, Iyathobelana ne-RoHS, I-No-clean and Water Clean Fluxes |

| Amafayela Ayadingeka | I-PCB: Amafayela e-Gerber (CAM, PCB, PCBDOC) |

| Izingxenye: I-Bill of Materials (Uhlu lwe-BOM) | |

| Umhlangano: Khetha & Faka ifayela | |

| Usayizi Wephaneli ye-PCB | Okuncane.Usayizi: 0.25*0.25 inch (6mm*6mm) |

| Ubukhulu Ubukhulu: 48*24 intshi (1200mm*600mm) | |

| Imininingwane Yezingxenye | Yehlisa Phansi kusayizi we-01005 |

| I-BGA ne-Ultra-Fine (uBGA) | |

| Izithwali ze-Chip ezingenantambo/CSP | |

| I-Quad Flat Package No-Lead (QFN) | |

| I-Quad Flat Package (QFP) | |

| I-Plastiki Leaded Chip Carrier (PLCC) | |

| I-SOIC | |

| I-Package-On-Package (PoP) | |

| Iphakheji Ye-Chip Encane (Iphimbo Elihle ukuya ku-0.02mm/0.8 mils) | |

| I-SMT Assembly enamacala amabili | |

| ukubekwa okuzenzakalelayo kwe-Ceramic BGA, Plastic BGA, MBGA | |

| Ukukhipha kanye nokufaka esikhundleni se-BGA's & MBGA's, kwehle kuye ku-0.35mm ukuphakama, kufika ku-45mm | |

| BGA Ukulungisa kanye Reball | |

| Ukususwa kwengxenye kanye Nokushintshwa | |

| Ikhebula nocingo | |

| Iphakheji yengxenye | Sika i-Tape, ishubhu, amareli, i-reel eyingxenye, ithreyi, inqwaba, izingxenye ezixekethile |

| Ikhwalithi | IPC Class II / IPC Class III |

| Amanye Amakhono | Ukuhlaziywa kwe-DFM |

| Ukuhlanza Amanzi | |

| Ukugqoka okuhlelekile | |

| Izinsizakalo Zokuhlola ze-PCB |

Ukuphathwa Kwekhwalithi

Ikhwalithi yinto ebaluleke kakhulu kithi.I-PCB ShinTech inendlela eqondisiwe yokuqinisekisa ukuthi ama-PCB akho akhiqizwa futhi ahlanganiswe ngekhwalithi ephezulu nokuvumelana.Akukho lutho ku-PCB ShinTech olushiywe ngengozi.Sisebenza kanzima kuwo wonke amaleveli okusebenza ukuze siqiniseke ukuthi yonke inqubo ichaziwe futhi imiyalelo yomsebenzi ibhaliwe ukuze sikwazi ukunikeza imikhiqizo namasevisi afanayo aphezulu kumakhasimende ethu.

1. Qonda okulindelwe yikhasimende kanye nezidingo.

2. Qhubeka udala futhi ulethe amanani amasha kumakhasimende.

3. Impendulo esikhalweni samakhasimende ngokushesha.Uma sihlangabezana nenkinga, siphatha yonke imicimbi enjalo njengethuba lokufunda ukuthi yini engahambanga kahle, kanye nendlela yokugwema ukwenzeka kabusha.

4. Sungula uhlelo lokuphatha ikhwalithi olusebenza kahle futhi uthuthukise ukusebenza kahle kohlelo ngokuqhubekayo.

Sibuyisela ikhwalithi yama-PCB akho kanye ne-PCBA ngokulungiselela amathuluzi alungile, sisebenzisa okokusebenza okufanele, ukuthenga izinto ezifanele, ukusebenzisa ukucubungula okufanele, nokuqasha nokuqeqesha opharetha abafanele.I-oda ngalinye lidlula ezinqubweni ezilawulwa ngokuqinile ngenhloso yokungagcini nje ngokukhulisa ukusebenza kahle ukuze kuzuze amakhasimende ethu kodwa nomgomo oyinhloko wokuletha ngokungaguquki umkhiqizo osezingeni elakhelwe kulokho okulindelwe yikhasimende kanye nezicaciso zebhodi.

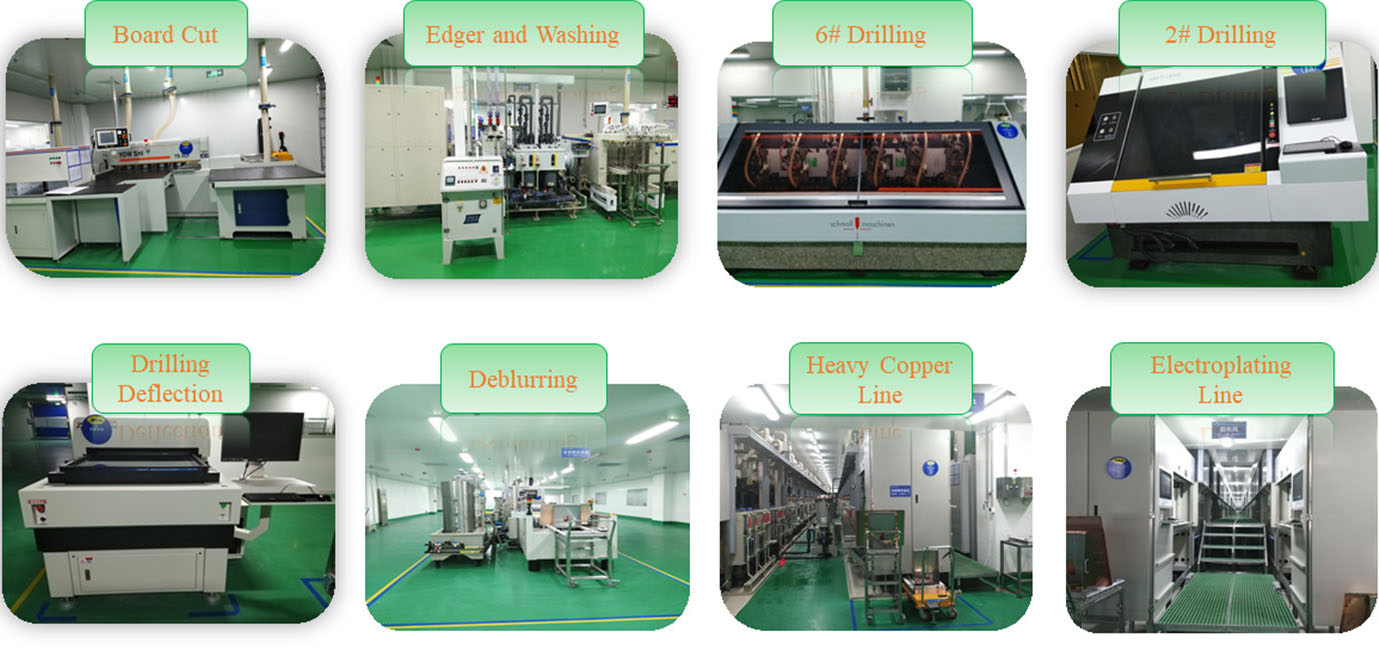

Izinsiza kanye nemishini yasendlini

Izinsiza zangaphakathi ze-PCB ShinTech zikwazi u-40,000 m2ngenyanga yokwenziwa kwe-PCB.Ngesikhathi esifanayo i-PCB ShinTech inemigqa ye-SMT engu-15 kanye nemigqa emi-3 ephumela ngaphakathi endlini.Ama-PCB akho awalokothi akhiqizwe obhidayo ophansi kakhulu ophuma echibini elikhulu lezimboni.Ukuze sifinyelele ukusebenza kwekhwalithi engavamile kusukela ekuhlanganisweni kwe-PCB, siqhubeka sitshala imali ezintweni zakamuva ezivumela ukunemba okunembile okudingekayo kuyo yonke inqubo yomhlangano, okuhlanganisa i-X Ray, i-solder paste, ukukhetha nendawo nokunye.

Ukuqeqeshwa kwabasebenzi

Indawo ngayinye yokukhiqiza nokuhlanganisa ye-PCB ShinTech inabahloli abaqeqeshwe ngokugcwele, ngoba inhloso yethu ebaluleke kakhulu ukuletha ikhwalithi.Ukuqeqeshwa kwama-opharetha kubalulekile.Kungumsebenzi wawo wonke ama-opharetha ukuhlola amabhodi njengoba enza inqubo yawo, futhi siyaqinisekisa ukuthi athole ukuqeqeshwa okuphelele futhi azuza ulwazi oludingekayo.

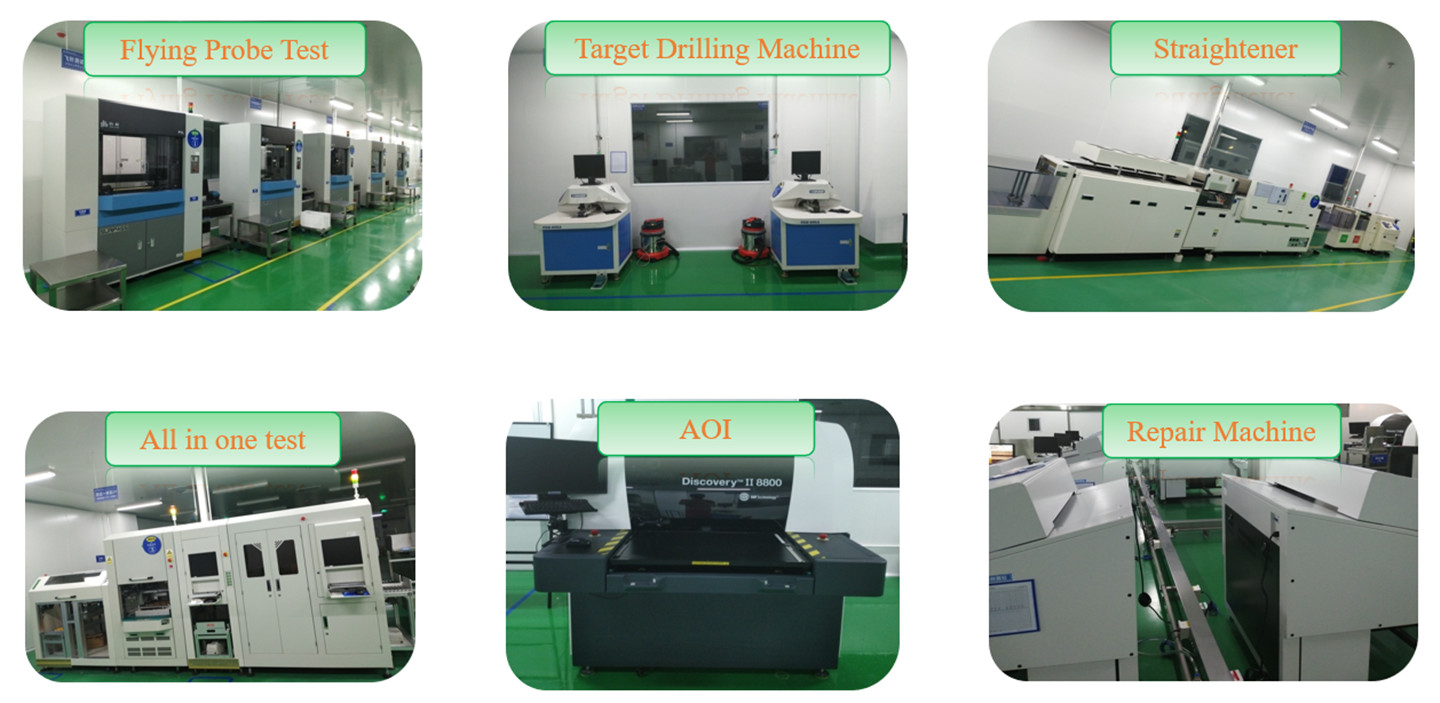

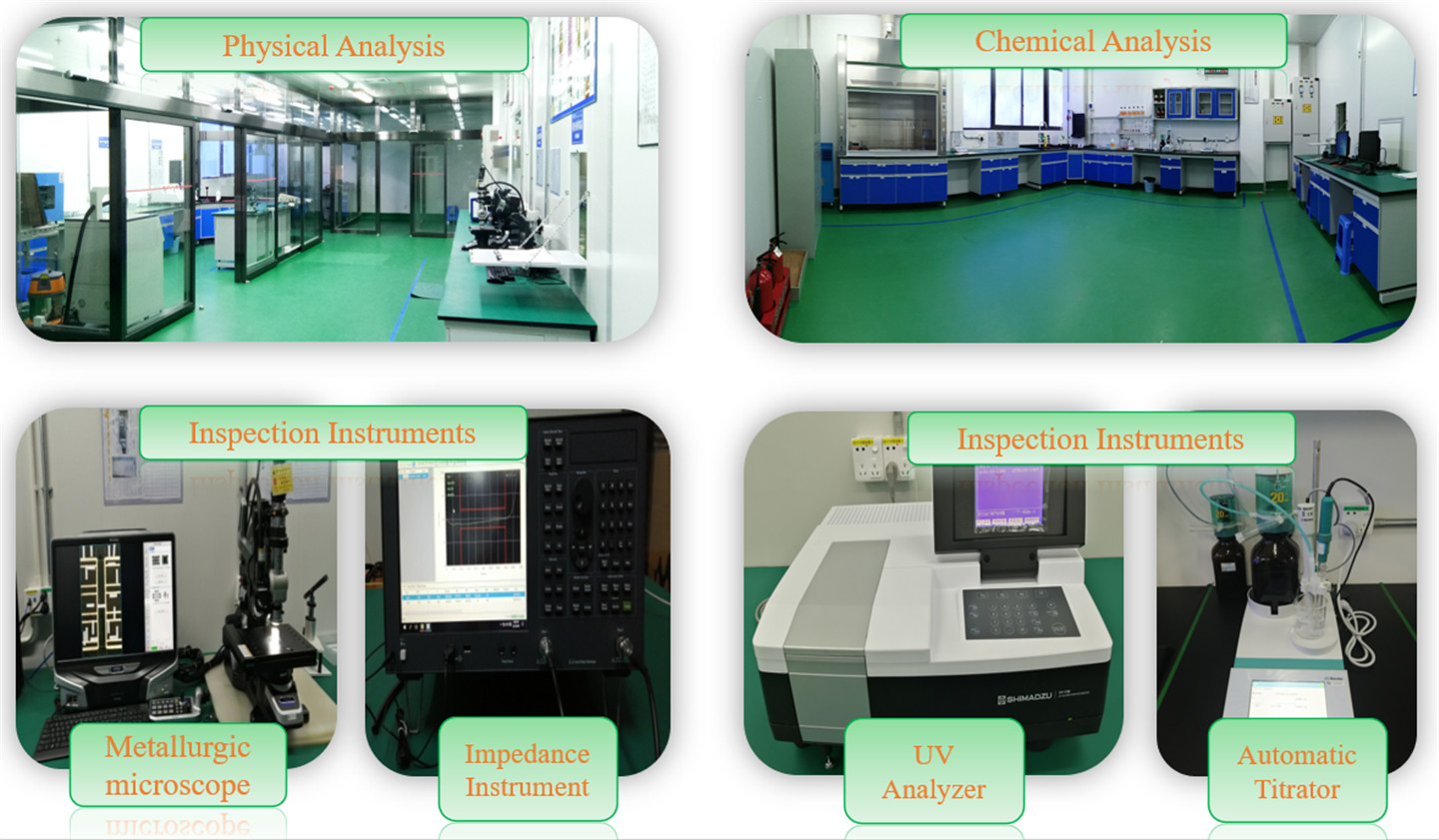

Ukuhlolwa nokuhlolwa

Kunjalo, ukuhlola nokuhlola nakho kuyagqama ohlelweni lokuphatha ikhwalithi lwe-PCB ShinTech.Sisebenzisa lezi ukuze siqinisekise ukuthi izinqubo zethu zisebenza ngendlela efanele.Lezi zinyathelo zikunikeza isiqinisekiso esengeziwe sokuthi ibhodi oyitholayo ilungile kumklamo wakho futhi izosebenza ngendlela efanele ngesikhathi sokuphila komkhiqizo wakho.Sitshale imali ezintweni zokusebenza ze-X-ray fluorescent, i-AOI, izihloli ze-fly probe, izihloli zikagesi nezinye ngenxa yale njongo.Amakhasimende amaningi awanazo izinsiza zokwenza izinto endlini.Sithatha isibopho sokuqinisekisa ukuthi ikhasimende ngalinye lithola lokho elikudingayo.

Lezi zinyathelo zichazwe ngezansi.

I-BARE PCB BOARD FABRICATION

● Ukuhlola okuzenzakalelayo (AOI) nokuhlola okubonakalayo

● I-microscope yedijithali

● Ukuhlukanisa izingxenye ezincane

● Ukuhlaziywa kwamakhemikhali okuqhubekayo kwezinqubo ezimanzi

● Ukuhlaziya njalo amaphutha nokulahlwa ngezenzo zokulungisa

● Ukuhlolwa kukagesi kufakiwe kuzo zonke izinkonzo

● Izilinganiso zokuthikamezeka okulawulwayo

● Isofthiwe ye-Polar Anstruments yokuklama izakhiwo ezivimbelayo ezilawulwayo namakhuphoni okuhlola.

UMHLANGANO WE-PCB

● Ibhodi elingenalutho kanye nokuhlolwa kwengxenye engenayo

● Amasheke okuqala

● Ukuhlola okuzenzakalelayo (AOI) nokuhlola okubonakalayo

● Ukuhlolwa kwe-X-ray uma kudingeka

● Ukuhlola okusebenzayo uma kudingeka

Izinsiza kanye Nezisetshenziswa

Izinsiza zangaphakathi ze-PCB ShinTech zikwazi u-40,000 m2ngenyanga yokwenziwa kwe-PCB.Ngesikhathi esifanayo i-PCB ShinTech inemigqa ye-SMT engu-15 kanye nemigqa emi-3 ephumela ngaphakathi endlini.Ama-PCB akho awalokothi akhiqizwe obhidayo ophansi kakhulu ophuma echibini elikhulu lezimboni.Ukuze sifinyelele ukusebenza kwekhwalithi engavamile kusukela ekuhlanganisweni kwe-PCB, siqhubeka sitshala imali ezintweni zakamuva ezivumela ukunemba okunembile okudingekayo kuyo yonke inqubo yomhlangano, okuhlanganisa i-X Ray, i-solder paste, ukukhetha nendawo nokunye.

2. PCBA

Izitifiketi

Izikhungo zethu ziphethe lezi zitifiketi:

● ISO-9001: 2015

● ISO14001: 2015

● TS16949: 2016

● UL: 2019

● AS9100: 2012

● I-RoHS: 2015

Thumela umbuzo wakho noma isicelo sekhwowuthi kithi kusales@pcbshintech.comukuze uxhumeke komunye wabamele ukuthengisa abanolwazi lwemboni ukukusiza uthole umbono wakho ukumaketha.